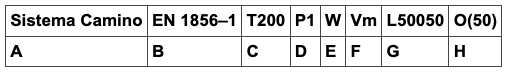

By purchasing the CANNA srl product you will receive an attached sheet, it is the Declaration of Conformity, through which the Manufacturer certifies the performance characteristics of the metal chimney components in relation to the standards:

- UNI EN 1856 -1 for the Metal Chimney System

- UNI EN 1856-2 for Metal flue liners and connecting flue pipes

The same declaration attests the CE MARKING of the product and the related FPC, Factory Process Control, both issued by the German notified body TUV Industrie Service GmbH TUV SUD Gruppe, making production compliant with the marking procedure identified by the system2+.

In the declaration of conformity you will find as required by norm:

- Product designation

- Construction features (material and insulating quality)

- Mechanical characteristics (compressive strength, traction and wind action)

- Direction of smoke flow

- Fluid dynamic resistance

- Thermal resistance, soot fire and minimum distance from combustible materials

- Resistance to frost and rainwater penetration

- Resistance to the diffusion of water vapor