Easy Holz Chimney

Complete

The solution for Wooden Roofs & Structures,

TP Tripla Parete®

Attention:The TRIPLA PARETE TP Easy HOLZ Chimney is the first to have solved the problem of the safety of wooden roofs and structures through the experience gained also in post-earthquake reconstructions. The only original, created by Eng. L. Morelli, the result of careful design and experimental evolution based on a 30 year installation activity, which has allowed to reach a level of high safety tested on field, such a high reliability of operation, difficult to find in recent partial imitations, of which it is recommended to be wary as recent and without a broad historical background.

The crossing section of chimneys for wooden roofs is frequently underestimated, or neglected, not considering that an element of potential high risk is introduced for the entire structure; the most serious danger comes not so much from operation in normal conditions (the exhaust gases are often much lower than the fire temperatures) but rather in sporadic situations such as an excessive load of wood in the stove or fireplace, or in the case of a internal soot fire.

In the latter situation, the internal flue in contact with the exhaust gases can reach very high temperatures up to 1000 ° C, making useless any preventive insulation action not studied and not certified, risking to compromise the integrity of the entire structure.

In addition, the type of ventilated roof, in the event of a fire, contributes to fueling it by means of ventilation, generating situations of particular attention; therefore it is easy, for what has been said, to understand the need to plan the crossing of the roof section.

- The only one who “breathes” … because ventilated

- Quick and easy installation

- No masonry work

- Total protection from high temperatures

- The first, the only, the original

- Complete waterproofness to rain

- Greater static strength against wind

- Roofing converse easy and safe

- Space reduced to +200 mm

- Linear design

The Easy HOLZ Chimney, designed by CANNA srl, combines the tranquility of the safest Technology with the aesthetic pleasure of true Design, protecting your roof from high temperatures, even in the event of a soot fire at 1000 ° C.

A synergistic collaboration with companies in North America, specialized in the wooden construction sector, has developed the design of the TRIPLEPARETE TP® system of CANNA srl, tested in its validity by a development and a construction application that hasbecome a school for decades.

The Technical & Design Office also makes it possible to install the duct entirely in view even in the rooms crossed, creating particular aesthetic suggestions in the tranquility of a guaranteed safety.

In fact, the exceptional characteristics of thermal insulation, reported during the certification tests, allow to combine the passion for the atmosphere of the fire with that given by wooden roofs and structures, in total safety, with the creation of TRIPLAPARETE TP® chimneys, crossing not only the roof section but also internal rooms and any floors.

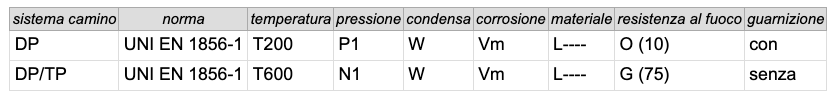

Technical Information

The Camino TRIPLAPARETE TP® system is covered by an important product insurance; each CANNA srl product is certified by tests performed (at the internal laboratory and / or external institutes notified), verified and approved with the issue of the relative designations certified by the strict German TUV.

How to read it:

Standard:reference standard number

Temperature:temperature class with tests up to 700 ° C (Class T600) at which the product guarantees its own operating safety

Pressure: Pressure class P1 positive (boilers), N1 negative (fireplaces and stoves) to which the product respects the gas seal required by the standard

Condensation: resistance to wet-wet condensation, resistance to condensation ensures the functioning of the product in its presence

Corrosion: corrosion resistance V2 defined through the severe laboratory test V2 at the Giordano institute

Material: material quality L50060, 50 = 316 LBA, 060 = thickness 0.60mm

Fire resistance:fire resistance and distance (mm) from combustible materials, G = YES: in the soot fire test, which can occur in the metal chimney installed due to bad maintenance, the product has passed the thermal shock test, at 1000 ° C for 30 minutes, during which the maximum temperature of combustible materials, placed at a distance in mm declared by the manufacturer, remained below 100 ° C as per standard

Available diameters (inside in mm): 100-150-200-250-300

External diameters: DP 25 = Di 50mm; TP 50 = Di + 100mm

*: consult the technical office for more information

The Easy HOLZ chimney is characterized by three essential points, which make it… the safest:

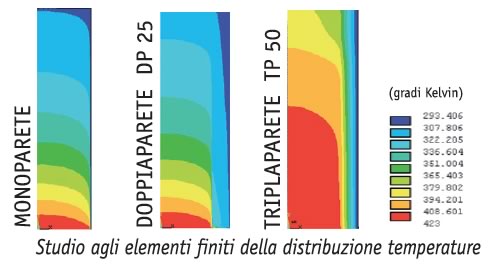

- the concept of third wall, TRIPLAPARETE TP® system, which offers, thanks to the interposition in the insulating layer of an additional shielding protection wall, an extraordinary guarantee of additional safety and functionality, even in extreme temperature conditions at 1000 ° C , unmatched without the presence of the third wall. In fact, the third wall introduces an additional reflective barrier to the heat transmitted by the inner wall, lapped and strongly stressed by the superheated exhaust gases, and in support of the first wall constitutes an additional safety duct

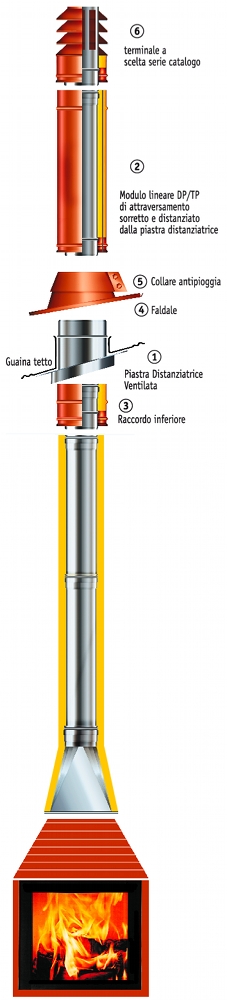

- The spacer flange®,the first designed without direct thermal bridges, and such as to allow, unlike other systems, to distance from the external wall of the duct both the roof by means of the lower shielding collar, and the covering sheath (thanks to the upper collar), ensuring a safe protection from high temperatures, and at the same time a total impermeability because it is facilitated in its application by the perfectly flat and free surface of the plate itself, provided with special holes that increase its thermal resistance

- the concept of ventilation, realized through the particular assembly of the walls and the spacer flange, designed to allow the metal chimney to “breathe” preventing overheating and allowing the evacuation of the heat accumulated in the underlying chimney, extending to it the concept of ventilated roof itself

Alternating insulation layers in high density (non-carcinogenic) fiber with aluminum certified 128 kg / mc resistant up to 1200 ° C.

For higher operating temperatures, an additional static or ventilated cooling air gap is introduced

The rain collar provides protection against any infiltration of the ventilated outlet section.

The rain converse, with the larger upper section of the duct, allows cooling by ventilation, It also waterproofs the exit area of the duct from the roofing and protects it from the eventual fall of dangerous incandescent debris and fumes, which could escapefrom the chimney in case of a soot fire. The lead side facilitates its connection to any type of roofing.

The lower fitting ensures that during installation the underlying duct is in any case always isolated near the roof, and allows the connection of the chimney to the underlying duct of the MP or DP series.

The lower fitting is not necessary if you continue with the TRIPLAPARETE TP® metal chimney system inside the room.

For high protection against acid condensation and high temperatures, the internal structure of the metal chimney is in stainless steel AISI 316L BA 0.6 mm thickness.

Furthermore, the terminal is interchangeable with the whole standard series in the catalog, or with design elements that the client can develop with our TECHNICAL & DESIGN OFFICE; however always designed in compliance with UNI 7129 with the minimum double outlet section of the internal section of the duct.

The spacer flangeis made with the required roof slope to measure, thanks to this it is fixed, more robust and statically more stable in the wind, without oscillations, due to the absence of mobile adjustment systems.

This allows to have a complete uniformity to the upper surface, planar and free, which facilitates the subsequent application of the layer of sheath ( never to be in contact with the space flange), without forcing points and breaking initiation of the same over time. The presence of a repeated puncture also increases its thermal resistance.

The upper collarsupports the entire chimney and distances it from the sheath, which is welded to it, and not to the external wall of the linear module, offering greater thermal resistance and therefore safety.

The spaced section of ring-shaped air passage that the upper collar also creates by distancing itself from the linear module, allows ventilation and therefore cooling of the same area, which, as designed, has never to be closed or obstructed by the subsequent application of the sheath.

In addition, in this way, any underlying chimney, placed to close the chimney in the under-roof space, remains ventilated avoiding overheating, since it is put in communication with the outside through the ventilated spacer flange.

The lower collarallows the installer to maintain the correct distance of the chimney from the perimeter wood, correctly drilling the through hole of the roof, or offering additional thermal protection to the perforated section of the ventilated roof thickness.

Attention: in any situation and system, the sheath, for total safety, is essential that it is never welded close to the external wall of the chimney or to the spacer flange.

Maximum safety … and designed for an easy and fast application, average time 30 minutes

1st phase

After having chosen the position, after holed the roof (with the appropriate template provided) and performed the safety firestop as indicated below (necessary for each system), only one person is sufficient to insert the Chimney Easy into the hole, already supplied complete in the terminal components (6), linear module (2), lower fitting (3) and spacer flange (1), fixing the same to the roof by means of the latter.

2nd phase

The roofing sheath has to be spaced from the spacer flange (1),which always remains ventilated and spaced from the duct for greater safety (the operation is facilitated by the flat and “clean” surface of the flange, designed free from annoying adjustments, for a result without infiltration safer over time), and such that it is never obstructed in ventilation, not even with the same sheath applied.

The flange is already equipped with the slope to fit your roofing, an important aspect as it makes it much more strong because it is fixed, with the advantage of greater wind resistance, and greater stability without oscillations.

3rd phase

The special roofing converse (4) and rain collar (5) are inserted from above to cover the outlet section for complete and safe waterproofing, being able to connect the converse to the roofing with the appropriate deformable lead side.

In this way, not only the section of the roof was created, but the metal chimney outlet complete and finished in every part, including the terminal and the converse system – rain collar included.

IMPORTANT: even if not necessary when installing Chimney Easy, however, in any condition and for any system, it is still important for safety to correctly carry out the firestop, or fireproofing of the exit section of the chimney. he operation consists in interrupting the ventilated passage crossed by the hole in the metal chimney with a wooden transverse barrier, in order to reduce the effects of a possible fire. In fact, the roof ventilation, indispensable, however causes a faster spread of the flames inside the ventilated package itself, making the event more subtle and dangerous in effects, as it is not immediately visible from the outside, and difficult in the extinguishing intervention since being the area difficult to reach. With the presence of a firestop barrier, the ventilation of the package is blocked, thus preventing it from feeding the flames in the event of a fire.

N.B .: the barrier must be at least 40mm thick, to give adequate fire resistance